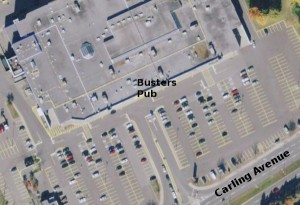

Did a pub meetup to have another look at the laser Dayton design.

Issues:

- It’s still tricky to lay out the wing perimeter. Interlocking parts combined with build on tissue has some problems to look at.

- Small parts are bad. The wing mound doublers are very small. You can see them on the laser cut.

- I manually cut one of the fuselage sides to make a gap in it. This is the grove for the toothpick. This worked well so I will include that in the next laser run.

- The landing gear is only .6g and the plane is 10g. That’s quite promising.

- Knocking about an inch off the rubber band motor loop makes hand winding easier.

- The glue stick is only used on four pieces. I’m wondering if it can be dropped. The spars warp a bit when the craft glue is applied but it flattens out in a few minutes. I suspect this will happen as long as we don’t use too much glue.