Category Archives: Sighting

12 minute airplane

freeflightml

I met Gary Hinze on the FreeFlightML (Free Flight Mailing List). He send me this message in July 2009.

The proposition in the Free Flight chat was that the Squirrel could be built in 6m by an expert. I must say, I did it in six minutes but it wasn’t easy.

It took me 12 minutes.

Darcy, I communicated with you when you first went on the Internet several years ago.

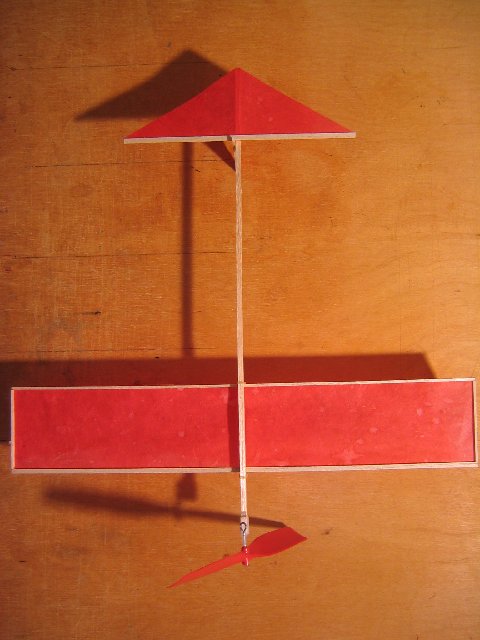

I just built my first Squirrel. I have always had a lot of trouble following directions. I made some changes. I hope they are improvements. You can see them all in this picture.

1. I used a 1/8″ x 1/4″ stick. Even this is heavier than necessary.

2. That necessitated a 1/8″ x 1/8″ x 1/2″ shim block so the Sig prop hanger would be a snug fit.

3. The stick tapers to 1/8″ thick in the last 2 3/8″ to make the tailplane parallel with the prop shaft.

4. The paper parts were cut out with cardboard templates. This wastes a lot less tissue. No scissors are necessary during construction. All wood parts are self locating on the paper patterns. (Several sets of tissue parts can be made at one time by stacking several sheets of tissue on top of each other.)

5. There is no center rib in the wing. The hold down stick does that job. It is glued in two places, to the wing leading and trailing edge spars, not to the paper.

6. There is no wing saddle. The hold down stick straps directly to the top of the stick with two dental bands, doubled to make them pretty tight. The top ends of the hold down stick are sanded to 45 degree tapers to make it easier to roll the bands on.

7. The wing and tailplane papers were folded in half to make center line creases to locate the hold down stick on the wing and the tailplane on the fuselage.

8. 1/16″ square wood was used for the wing trailing edge, tip ribs and winglet spars.

9. The winglet spars were located 3/4″ back from the leading edge.

10. The wing was mounted with the paper on the upper surface. That gives the wing 2 degrees of effective incidence. Added to the 3 degrees of downthrust, that is 5 degrees attack angle. As designed, the wing has about zero degrees of effective incidence and 3 degree attack angle from the downthrust only.

11. No wing incidence shim is necessary.

12. The winglet spars are glued to the outer faces of the wingtips, due to the wing being “upsidedown”.

13. The fin spar is extended 1/4″ below the bottom of the stick to hold the motor. I may file a round indentation in the back of the spar to hold the motor in place. With the motor I intend to use, the motor will never come loose, unless it gets into a thermal, and in that case your motor dethermalizer will come into play. No toothpick or thread are necessary for the motor hook.

14. The back corner of the tailplane aligns exactly with the end of the stick. The root chord of the fin is 1/8″ longer than the root chord of the tailplane so it too aligns exactly with the end of the stick, but the fin spar can go directly in front of the tailplane spar. The bottom edge of the fin paper aligns exactly with the bottom edge of the stick taper.

The finished plane weighs 5.9 grams. I used 11# wood for the stick and 14# wood for the spars. I also used a Japanese paper that weighs 26 grams per square meter because the unsupported tissue edges seemed rather fragile in fine tissue. The distance between the hooks is 9 1/2″. I will use a handy 20″ loop of 1/16″ Tan Super Sport to fly it.

It could be made quite a bit lighter with lighter wood, thinner tissue with thread reinforced edges and a North Pacific 5 1/2″ prop assembly. That prop assembly weighs a gram less than the Sig unit because the prop is much thinner.

I moved the wing until I got a slow, steady descent. The CG was at 13/16″, about a third of the chord, pretty close to the winglet spar position.

There are 18 parts in this Squirrel.

1 1/8″ x 1/4″ x 12″ balsa motor stick

1 1/8″ x 1/8″ x 1/2″ balsa nose spacer

1 1/16″ x 1/8″ x 12″ balsa wing leading edge

1 1/16″ x 1/16″ x 12″ balsa wing trailing edge

4 1/16″ x 1/16″ x 2 1/16″ balsa wingtip ribs and winglet posts

1 1/16″ x 1/8″ x 2 1/2″ balsa fin spar

1 1/16″ x 1/8″ x 6″ balsa tailplane spar

1 1/16″ x 1/8″ x 3″ balsa wing hold down stick

1 tissue wing

1 tissue tailplane

1 tissue fin

2 dental hold down bands

1 5 1/2″ propeller assembly

1 19″ loop of 1/16″ rubber motor

I have not had an opportunity to fly it under power, finished it after dark, been warned by the police about being in the park after dark. I expect to have a chance to fly it tomorrow and report results.

Gary Hinze

Wycliffe College Cub Scout Pack based in Gloucestershire, UK

Jon Ingram of Wycliffe College Cub Scout Pack based in Gloucestershire, UK prepares for their first Squirrel workshop for their Air Activities badge. The workshop was on September 26, 2009.

They organized a photographer for their event so we should receive an update fro then with the picture from their actual workshop.

The pictures below are from Jon and his son preparing. He said that they would have ten adults helping during the workshop with 24 children.

Here is the plan for the day:

Cubs Air Day Schedule of Events

9.30am-10am Cubs arrive and meet in Barn

10am-10.15am Roll Call, Welcome, Agenda & Introductions

10.15am-10.45am Airfield Safety Briefing

10.45am-11.15am Model Building Part One*

11.15am-12.15pm Different types of flying machines*

12.15am-1pm Flying Weather*

1pm-1.30pm Lunch*

1.30pm-2pm Model Building part Two*

2pm-3pm Model Flying and Competition*

* Groups of no more than six will be taken for a tour of the hangers and aircraft and Individual cubs will be allocated flights throughout the course of the day

September 18th, Squirrel kits not received yet Here’s a comment I received from Jon: “The strike here is planned next week but I learnt that a series of wildcat unofficial strikes have been happening…..”

So I boxed up another order for him and sent it by Purolator service, 2 business days. The bill was $94.00CA.

September 22nd Squirrels finally arrive:

Hi Darcy,

I received the 2nd consignment today via UPS. The first bunch has not yet arrived. I will let you know as soon as they turn up. I am busy trying to sort out a visit from the BAE Spitfire on Saturday. If it flies over I will send you some footage!

A test build commences tonight with my six year old son…..

Regards

jon