I was asked to clarify how to add an aileron to a Squirrel (or any stick and tissue model plane for that matter).

I was asked to clarify how to add an aileron to a Squirrel (or any stick and tissue model plane for that matter).

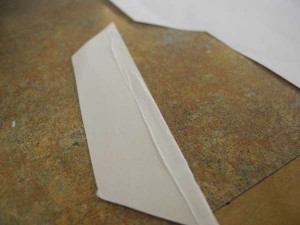

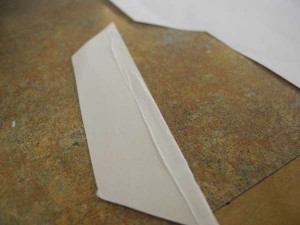

I use ordinary copy paper and cut out a rectangle or a tapered rectangle. Come think of it any shape will work as long as there is a long edge to attach to the wing.

20lb Copy paper is about right. I tried with tissue and it’s too light to keep it’s shape.

Scissors are best. In my example I actually used a hobby knife since I was in a cafeteria and I found my hobby knife before I found my scissors. 🙂

For a Squirrel I usually make the aileron about 3 inches long. I suppose 4 inches is good too. An inch wide is about right. In the example to the right I made it a little narrower than that.

For a Squirrel I usually make the aileron about 3 inches long. I suppose 4 inches is good too. An inch wide is about right. In the example to the right I made it a little narrower than that.

If you have a glue stick you can put a thin layer along one of the long edges. I like a glue stick since you can probably easily remove the aileron if decide you don’t like it.

In the event you use white glue or craft glue be sure to use a toothpick or something to smear a thin layer along a long edge.

I used a bit much glue in the picture. But I was in a rush since I was about to do a flying session at a seniors residence.

I used a bit much glue in the picture. But I was in a rush since I was about to do a flying session at a seniors residence.

You can then glue it to the trailing edge (back) of one of the wings. Any wing will work but I usually use the left. Most of my Squirrels turn right so I put it on the left and then bend it up a bit to bring the left wing down during flight.

Many people like having two ailerons. But I like just one. If it doesn’t work well enough I either make a bigger one or I make another one for the other wing.

Once you have an aileron (or two) on your airplane you can experiment bending them in different directions to affect the direction of flight.

Once you have an aileron (or two) on your airplane you can experiment bending them in different directions to affect the direction of flight.

If you have one I think it’s the easiest to start with.

But if you have two, there are a lot of options to try.

If you bend one up and one down, it will be twice as effective.

If you bend both down at the same time, then it is actually referred to as flaps or flap. Flaps can reduce the speed of the airplane and is used for landing and takeoff for many airplanes.

If you bend both up it’s called spoilers. This is used for breaking and can be used just before landing as a way of bleeding of extra speed if the plane is travelling a little too fast.

For a Squirrel or any other simple stick and tissue model a single aileron can help get the airplane to go straight or in the right turn radius to suit your flying venue.

How an aileron works

An aileron on the left wing will raise the wing if it is bend downward (turning the plane right). It will drop the wing if you bend it up.

On the right wing it is the same except raising the wing will turn the plane left.

As a rule if you change the aileron setting of an airplane you need to change the pitch settings too. If you make the plane turn more then you need to make a pitch adjustment to raise the nose. If you make it turn less then the nose will raise so you need to make a pitch adjustment to drop the nose.

On a Squirrel the pitch is controlled by the wing position. To raise the nose move the wing forward. To drop the nose move it back.

Adjust aileron and pitch in small increments.

I was asked to clarify how to add an aileron to a Squirrel (or any stick and tissue model plane for that matter).

I was asked to clarify how to add an aileron to a Squirrel (or any stick and tissue model plane for that matter). For a Squirrel I usually make the aileron about 3 inches long. I suppose 4 inches is good too. An inch wide is about right. In the example to the right I made it a little narrower than that.

For a Squirrel I usually make the aileron about 3 inches long. I suppose 4 inches is good too. An inch wide is about right. In the example to the right I made it a little narrower than that. I used a bit much glue in the picture. But I was in a rush since I was about to do a flying session at a seniors residence.

I used a bit much glue in the picture. But I was in a rush since I was about to do a flying session at a seniors residence. Once you have an aileron (or two) on your airplane you can experiment bending them in different directions to affect the direction of flight.

Once you have an aileron (or two) on your airplane you can experiment bending them in different directions to affect the direction of flight.